"The broad range of solutions for a wide variety of customer product and process requirements is testament to our curiosity, customer focus and innovative spirit.

The interdisciplinary approach during the development phase is our critical success factor for achieving success in this exciting and challenging working environment."

Your development partner for intelligent solutions made of plastic and metal

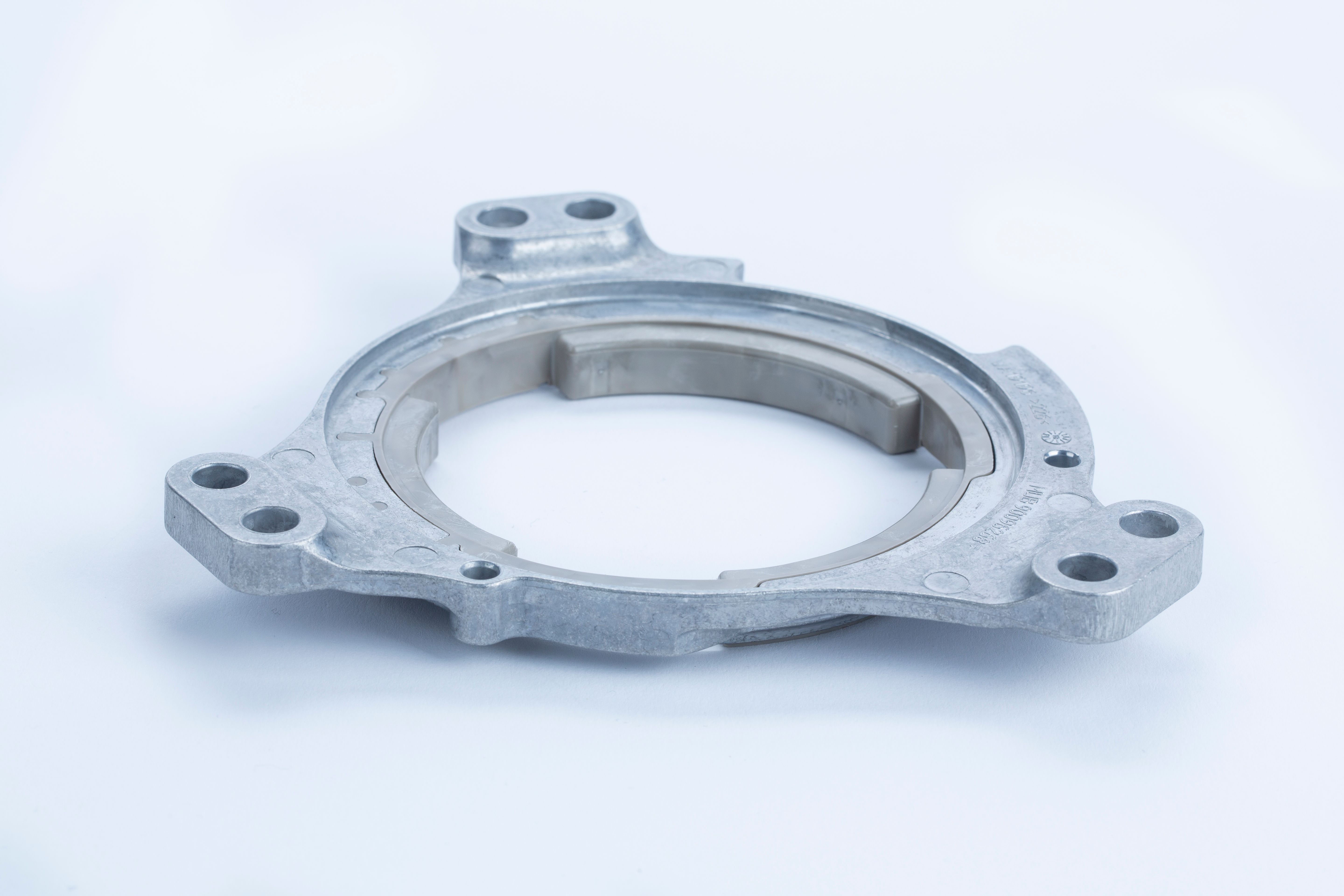

Wagner is more than just a manufacturing company – we see ourselves as a strategic development partner for sophisticated components and assemblies made of plastic, metal and hybrid material combinations. Our customers in the automotive, electronics, mechanical engineering and building services engineering industries benefit from a unique combination of material-neutral consulting, in-depth engineering expertise and an international production network with best-cost locations. This combination allows us to combine development strength with global manufacturing expertise, creating the basis for economical, high-quality and sustainable product solutions.

Our strength lies in our ability to translate complex technical requirements into economical and functionally optimised solutions. While many suppliers limit themselves to individual process steps, Wagner offers the entire value chain from a single source: from analysis and material-neutral consulting to development, simulation and prototyping to series production and assembly with functional responsibility. In doing so, we take technical, economic and ecological aspects into account in equal measure and create solutions that reduce weight, lower costs, integrate functions and minimise complexity.

Our engineering expertise is deeply rooted in the company's DNA. With over 75 years of experience, state-of-the-art infrastructure and an interdisciplinary team of engineers, designers and manufacturing specialists, we deliver innovative, tried-and-tested solutions. Whether aluminium and zinc die casting, high-performance plastics or hybrid material systems – Wagner masters all technologies and combines them specifically for optimal results. In addition, we support our customers with simulations, feasibility analyses and design-for-manufacturing approaches to shorten development times and increase product quality.

Furthermore, we attach great importance to close and transparent cooperation with our customers. Through clearly structured development processes, early communication and consistent quality planning, we secure every project from the outset. Our aim is to create solutions that not only impress today, but also meet future requirements for efficiency, sustainability and performance. Wagner stands for technical innovation, reliability and partnership-based development at the highest level.

Our USPs at a glance:

• Material-neutral consulting with a focus on design-to-cost

• Hybrid solutions for metal substitution and function integration

• Series production at best-cost locations with a high degree of vertical integration

• Traceability and quality assurance in accordance with IATF 16949, ISO 9001 & 14001

• Lean production & Industry 4.0 integration