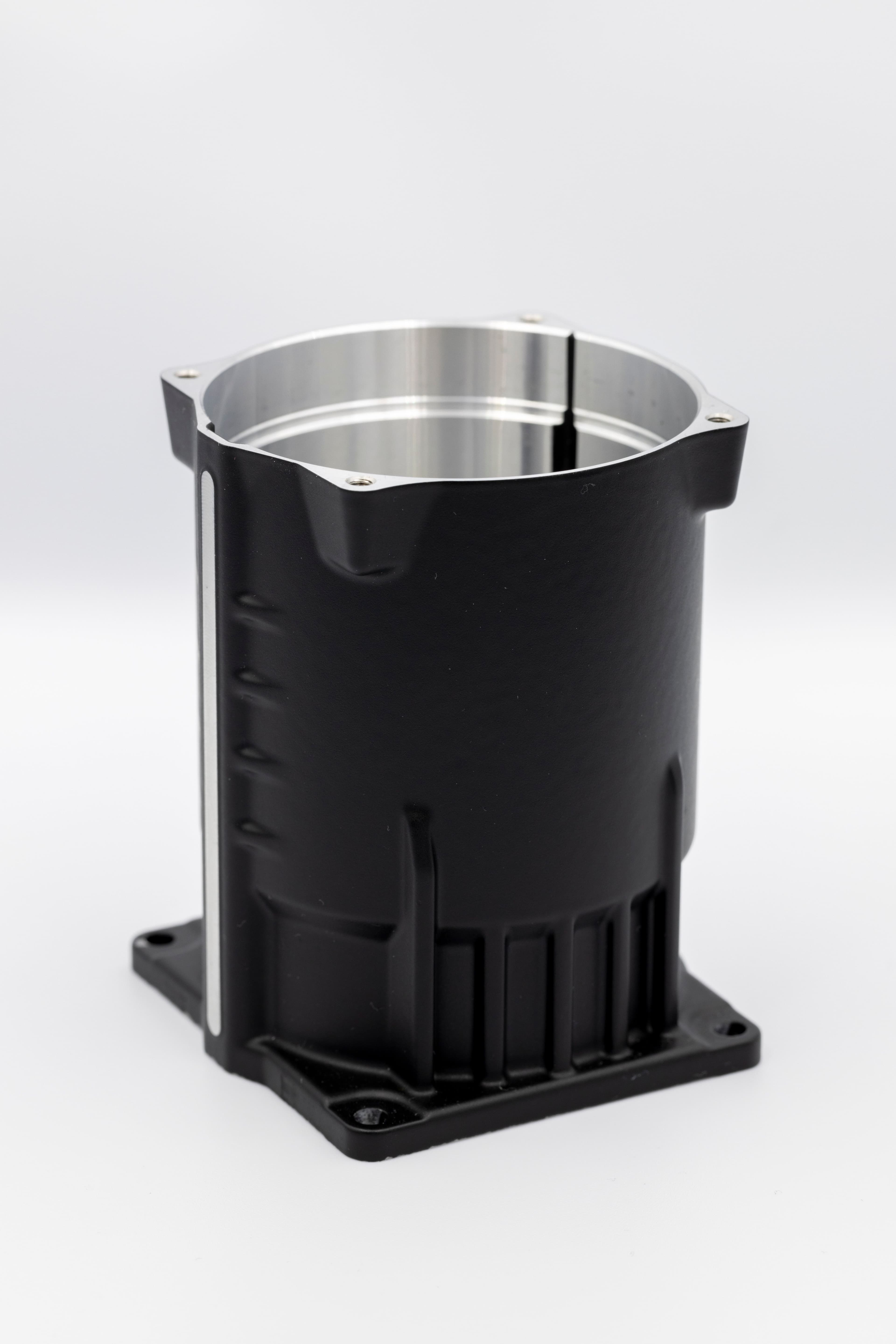

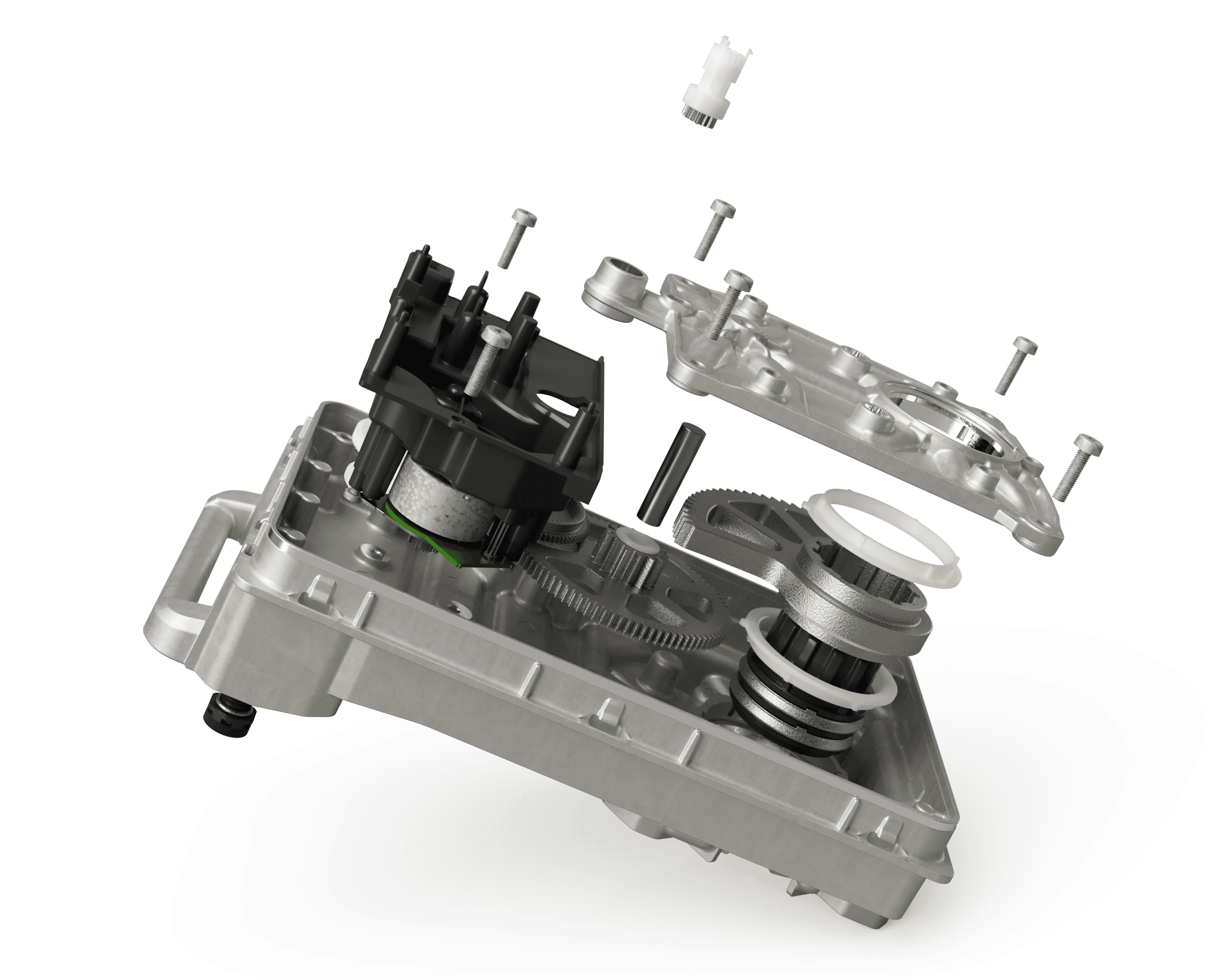

Hybrid solution

In this automotive component, the best properties of plastic are combined with the best properties of aluminum. The result is a hybrid solution that only dissipates heat from the power-electronics where needed. The rest of the housing is electrically insulating, very lightweight, EMV-shielding, and, through a clever clip connection, saves time-consuming screwing processes during final assembly.

Weight reduction

Weight reduction through the use of EMI-shielding plastics instead of significantly heavier aluminum. In addition, reduction of CO2 footprint for the vehicle through lower part weight.

Added value

-30%

Cost reduction

Cost reduction through an ejected finished injection molded component. No rework required. Furthermore, cost reduction for customer since screwing process is not required in his assembly anymore.

Added value

-20%

Function integration

Integration of snap connectors for assembly. No screwing required at the customer’s site.

Added value

- 6 parts