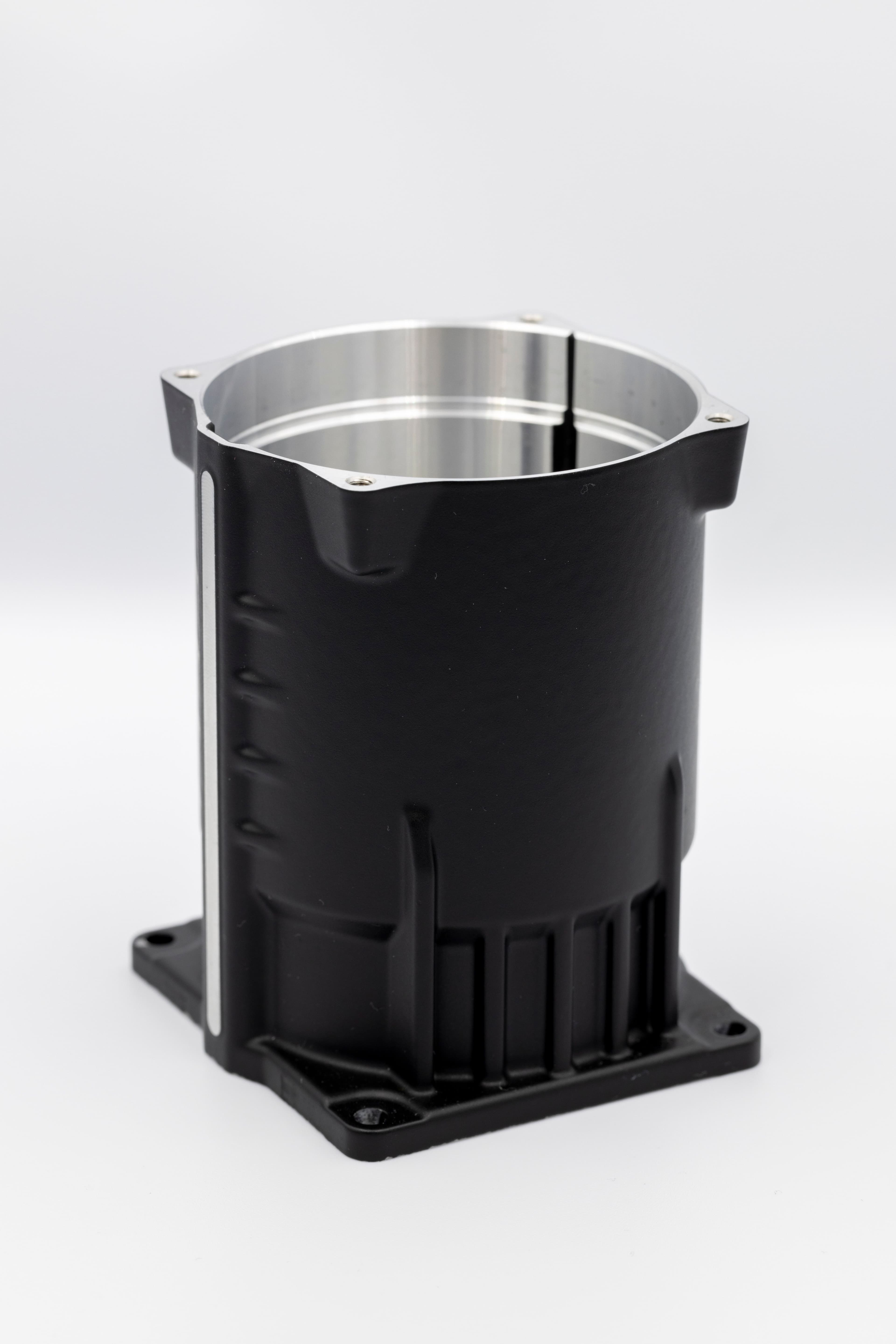

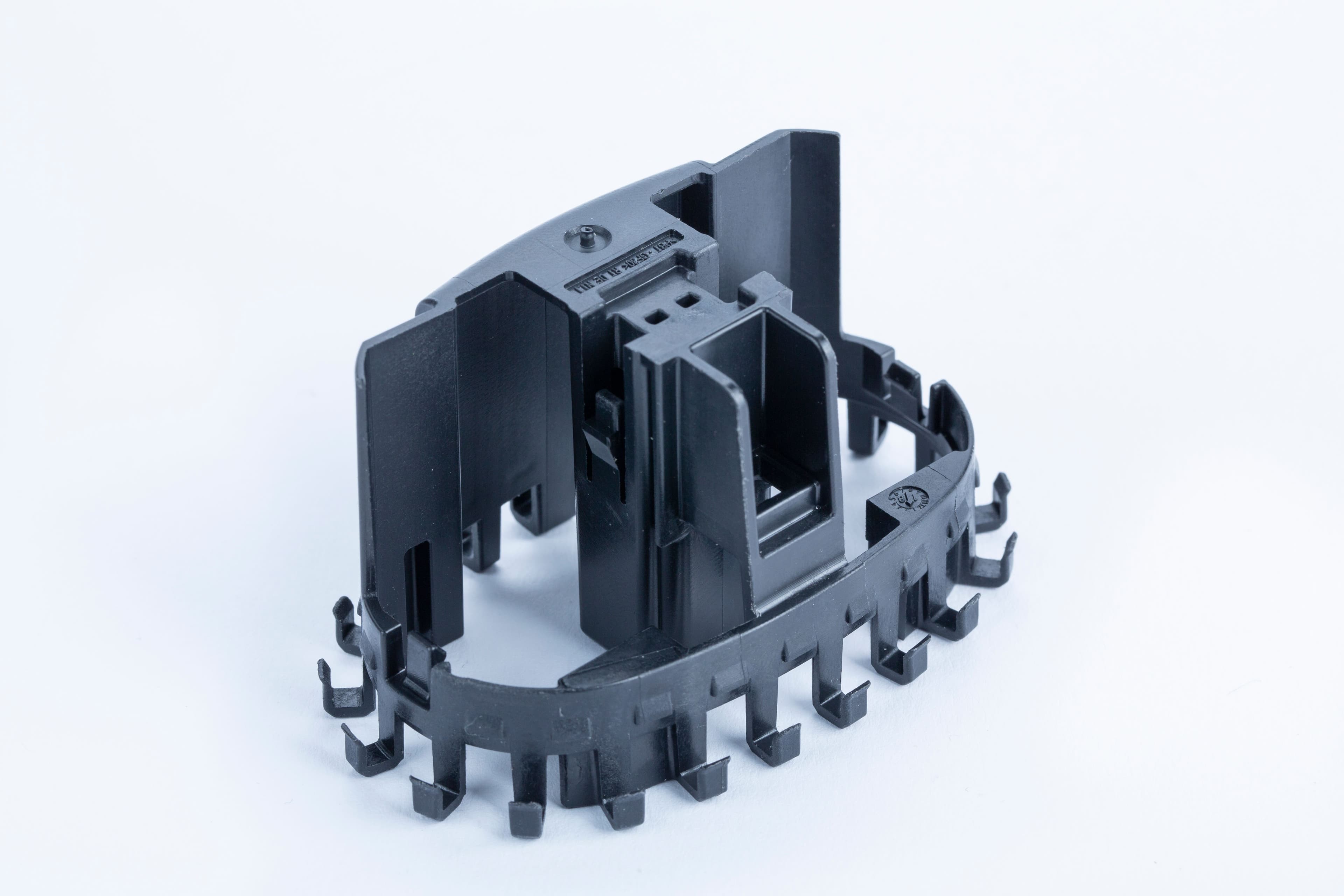

Hybrid metal-plastic solution

By directly overmolding the plastic friction surfaces onto the die casting component, labor-intensive assembly at the customer’s site is eliminated. The best properties of aluminum are combined with the best properties of plastic, resulting in a compact component with high strength, excellent sliding properties, and precise fits.

Weight reduction

Weight reduction through optimized hybrid aluminum-plastic connection.

Added value

-10%

Cost reduction

Finished hybrid component. No assembly required at the customer’s site. Significant improvement of customer's system performance resulting in less wear and tear of the belt tensioner system in use.

Added value

>20%

Complexity reduction

The entire value creation takes place at Wagner. Integration of several suppliers and production processes into one solution. Wagner takes over the responsibility for the sum of the tolerances of the system.

Added value

- 3 assembly parts